| Model |

Flow |

Inlet and Outlet |

Dimension mm |

Weight |

Heater Power |

| m³/min |

DN |

L |

W |

H |

Kg |

kW |

| ZDC3000SF |

45 |

100 |

3100 |

1550 |

2750 |

3900 |

27 |

| ZDC4000SF |

60 |

125 |

3250 |

1700 |

2900 |

4800 |

36 |

| ZDC5000SF |

76 |

125 |

3350 |

1800 |

3050 |

5300 |

50 |

| ZDC6000SF |

100 |

150 |

3550 |

2150 |

3250 |

6900 |

60 |

| ZDC7500SF |

124 |

150 |

3700 |

2400 |

3350 |

8600 |

75 |

| ZDC9500SF |

150 |

200 |

3800 |

2500 |

3400 |

10800 |

100 |

| ZDC13000SF |

210 |

200 |

4550 |

2900 |

3600 |

14500 |

130 |

| ZDC15000SF |

250 |

250 |

4600 |

3050 |

3700 |

16500 |

160 |

| ZDC20000SF |

300 |

250 |

4900 |

3500 |

3900 |

19500 |

190 |

| ZDC25000SF |

370 |

300 |

5050 |

3750 |

4100 |

23500 |

220 |

| ZDC30000SF |

450 |

300 |

5250 |

3850 |

4200 |

26500 |

280 |

* Final dimensions and weights may vary slightly depending on the actual situation

Correction Factor

| Work Pressure (BarG) |

4.5 |

5 |

6 |

7 |

8 |

9 |

10 |

| Correction factor |

0.679 |

0.748 |

0.874 |

1.000 |

1.126 |

1.252 |

1.380 |

Operating conditions

√ High temp. Inlet temperature:≥110℃

√ Inlet temperature:≤38℃

√ Ambient temperature:1-45℃

√ Standard Working Pressure:0.7Mpa

√ Power:AC380V/3P/50Hz

√ Cooling Water: ≤32℃

Standard configuration

√ PDP:-20℃

√ Adsorbent life:3 years

√ Valve with Stainless Steel Core

√ PLC Control,Color screen

√ Dewpoint display and energy saving module

√ Valve position monitoring

Optional configuration

√ PDP:-40℃

√ High temp. inlet temperature:≥90℃

√ Steam heater

√ Communication telex function

√ Tower insulation

ZDC Heat Of Compression Zero Purge Desiccant DryerDetails

ZDC Heat Of Compression Zero Purge Desiccant DryerDetails ZDB Blower Zero Purge Desiccant DryerDetails

ZDB Blower Zero Purge Desiccant DryerDetails ZDB+ Blower Zero Purge Desiccant DryerDetails

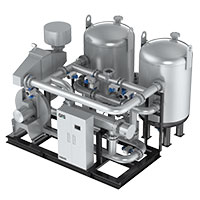

ZDB+ Blower Zero Purge Desiccant DryerDetails ZDC-SF Double Intake Heat Of Compression Zero Purge Desiccant DryerDetails

ZDC-SF Double Intake Heat Of Compression Zero Purge Desiccant DryerDetails ZDC+ Superior Heat Of Compression & Blower Zero Purge Desiccant DryerDetails

ZDC+ Superior Heat Of Compression & Blower Zero Purge Desiccant DryerDetails